Aisle Access

Contractors are not to block aisle access. All waste must be removed by contractors and disposed of in a sustainable manner. Designated emergency aisles, portable fire extinguishers and fixed installations must be kept clear at all times - items left in these gangways are liable to removal and may be disposed of without liability. Lifting contractors are not permitted to place and block freight loads in designated emergency aisles.

Anchoring Stands

All stand structures must be completely self-supporting and stable. Direct suspension may not be made from the roof of the exhibition halls, nor may any fixing be made to the structure of the building. Nothing may be drilled, attached, or bolted to the hall floor.

Build Timetable

Please see the full build timetable here.

Stand construction and finishing must be within the given build up timetable. Failure to complete the stand within the published time schedule will result in additional fees, invoiced to the Exhibitor. Exhibitors and contractors should plan to ensure that late working is not required

Bridging

Stand bridging is not permitted.

Building Works & Fixings

No paint, adhesives, fixings, attachments to / or penetration of the fabric, structure or floors of the venue shall be permitted. In case there’s a damage to the venue, a fine will be imposed as per the quote that Roar B2B receives from the venue to make good their property.

Complex Structures

For all Complex Structures a fee of approx. £435 + VAT will be charged by Roar B2B direct to you or your contractor to cover such on-site assessments and certificate costs. Please make sure that your contractor is aware of this charge in order to avoid delays in construction approval.

Complex structures are defined as any form of construction of any height, which would normally be designed by an engineer and/or has been found to provide significant risk via a Risk Assessment.

Submission Procedures

We must submit full details of all complex structures to the venue no later than 28 days prior to tenancy. Permission to build any complex structure will not be given until the venue has received copies of the following (written in English):

- Detailed, scaled structural drawings showing:

- Plan views of each storey of the stand/structure

- Sections through each storey of the stand/structure

- Elevations including full steelwork and staircase details

- Width and position of gangways within the stand

- Floor and/or roof loading

- Specifications of materials used

- Structural calculations

- Risk assessment (to include fire hazards) and method statement

- Written confirmation from an independent structural engineer, with adequate professional indemnity cover, that the design is safe for its purpose

Each item of information should state the event name and stand number. Complete sets of information only should be submitted, together with a plan showing the location of the stand within the exhibition.

If any complex structure is modified after the submission of the above information, plans must be re-submitted with details of all modifications and a structural engineer’s confirmation that the final overall design is safe for its purpose.

Any stand which is a complex structure or space only stand on which large numbers of people could gather will need a fire risk assessment simply because of the escape issue.

Examples include:

- Lighting rigs

- Raised walkways

- Ramps

- Sound/lighting towers

- Stands between 4m and 6m in height

- Temporary tiered seating

- Viewing/service platforms

- Stand designs that include a platform above floor level to which members of the public have access; including stand designs that include ramps to platforms of over 600mm

- Stages of 600mm and over in height and all stages for public use are deemed to be complex

- Non-standard rigged items, eg box banners made from plywood.

- Multi-storey stands, stands with viewing/service platforms, raised walkways, sound/lighting towers, temporary tiered seating.

The organiser will obtain Certification by a structural engineer, certifying them as safe and constructed in accordance with the designer’s specification and sound and safe for their intended purpose.

Your stand approval is always subject to onsite inspection. A structural engineer will be on-site during the build period to inspect your stand. All complex stands must be completed by 14:00hrs on the last build day in order for the sign off to be completed and the certificate issued.

Compressed Gas

Use of compressed gases will only be permitted where essential and only by exception and these must be recorded on the stand risk assessment.

The NEC Works Department is responsible for supplying these services to stands. Each service operates as follows:

- Compressed air - 3/4" B.S.P. isolating valve

- Natural gas - 1" B.S.P. isolating valve

- Water - 1/2" B.S.P. stopcock

- Drain - 1 1/2" B.S.P. coupling

The NEC Works Department will apply a surcharge of 40% on orders received on site. If you require any of these services, please see Venue Services

Dressing of back walls

Finishing the reverse of any wall over 2.3m in height that overlooks neighbouring stands in a neutral colour. All cables and wires on the backs of walls must be hidden from view.

Doors

Doors should open outwards in the direction of escape, those that are on a gangway should be set back so that the door doesn't intrude onto the gangway. All doors should be fitted with a vision panel of clear glazing at sight level (including for wheelchairs) giving a zone of visibility between 500mm and 1500mm above floor level. Doors should also be a minimum of 800mm

E-Guide

All stands must comply with the regulations as set out in the eGuide.

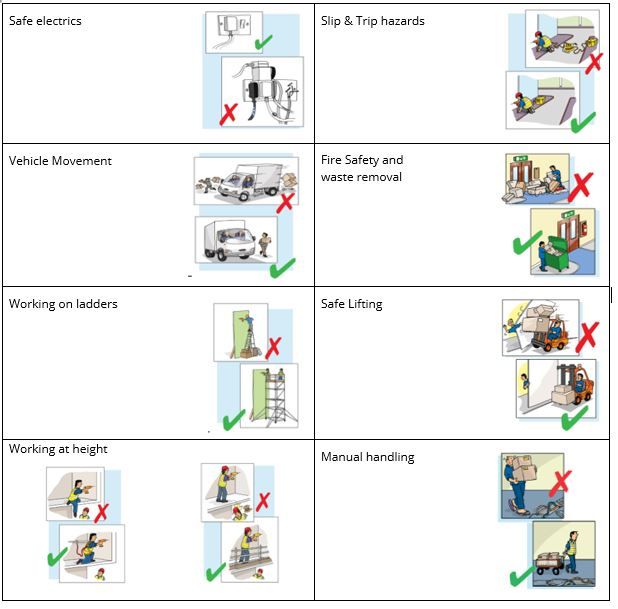

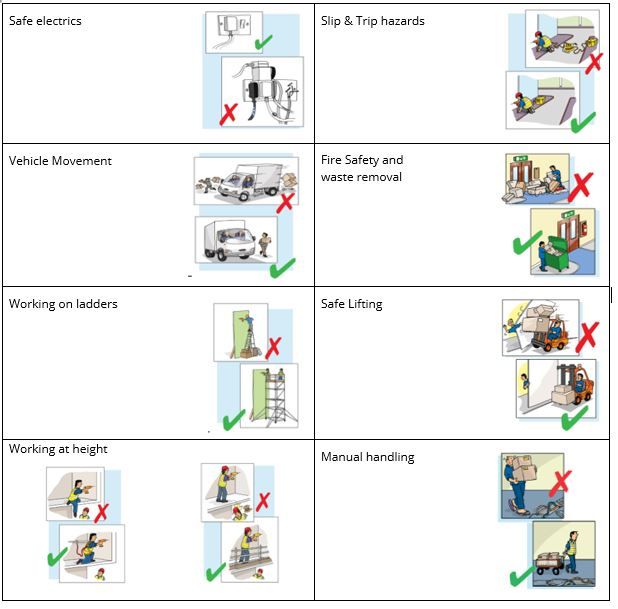

Electrics

- All electrical equipment and exhibits must be guarded to prevent accidental contact with live terminals. Items intended for use on stands must be PAT tested and labelled accordingly.

- Electrical cables must not be run under carpet or up stand fitting support posts. Cables on the floor which may be walked on must be protected by conduit or with protective ramping (tape is not acceptable).

- All on-site electrical work must be carried out by a qualified, competent person and inspected by the appointed electrical contractor, prior to energising. Testing charges will apply.

- Use of the venue’s electrical sockets is not permitted and cables must not cross gangways. Once power has been energised during build-up, it will be switched off each night, including the pre-open night. If you need power overnight, you will need to order a 24 hour supply from Electric contractor.

- Extension leads may be used to provide multiple socket outlets. These must not exceed 4 sockets and a cable length of 2m (uncoiled) Extension leads MUST NOT be chained together. ONE EXTENSION LEAD IS ALLOWED PER SOCKET ORDERED. The power used for appliances via the extension lead should not exceed the wattage of the power socket ordered.

- Power to your stand will be switched off 30 minutes after the show closes each day and will not be switched back on until the following morning.

- On the last open day, power will not be switched back on after the show closes under any circumstances, due to the hazards presented during the breakdown of stands. If you need a supply beyond this time, please arrange this with the electrical contractor.

- All electrical installations must comply fully with the eGuide The following is a brief summary of key points: Exhibitors own light fittings must be secured using clips or heavy-duty electrical ties and earth bonded appropriately. Light fitting flex must not be left hanging in coils or wrapped around any part of a metal structure. Cable ties must be used to secure flex to the structure. Spotlights/floodlights/halogen lamps, etc must be guarded and mechanically fixed, so as to prevent risk of injury to persons. All lighting must be kept at least 300mm away from muslin/fabric ceilings and other combustibles. Lighting circuits must not exceed 1,000 watts. They must not be looped or connected to power circuits.

- Electrics can be ordered through the supplier in the Order Form Page. All questions regarding power requirements should be directed to the supplier.

- The supplier standard 3-pin English 13A socket-outlets, but with four different power ratings. The list below indicates the type of equipment that can be used with each of the power ratings:

Examples of Power Requirements

2amp (500w) Socket - Laptops, Computers, TV’s, DVD’s, Lighting up to 500w

5amp (1000w) Socket - Small Domestic Microwaves, Lighting up to 1000w

10amp (2000w) Socket - Small Nespresso Machines, Small Vacuum Cleaner, Hair Dryers. Lighting not permitted

13amp (3000w) Socket - Vacuum Cleaner, Coffee machines, Jug Kettles, Urns. Lighting not permitted

Note: Lighting circuits may not exceed 1000w

- The list indicates individual items that can be used with each socket, except for the 500W socket above. All sockets are supplied on daytime power only unless 24-hour continuous power is requested and quoted for.

- Actual power requirements will vary dependent upon the individual equipment used. All electrical equipment has a Rating Plate that shows its power consumption in Watts (W) or kilowatts (kW). You should carefully examine all equipment to be used and calculate the exact power usage AND the positioning of electrical items on the stand before ordering your electrical power requirements.

- Additional power requirements ordered onsite will incur surcharge on the standard rate

- Exhibitors MUST provide a positioning diagram showing the required position of sockets / lights. Should electrical items installed by electrical contractor require moving onsite there maybe an additional charge.

- Exhibitors requiring a main only supply with a cee form connection for machines or own distribution should contact the supplier directly for a quotation.

- Island sites will require an independent main supply as per venue regulations. Order Form socket prices do not apply to stand alone / island sites. Please contact the supplier.

Enclosed Areas

Alternative means of escape and adequately maintained general and safety lighting with exit notices illuminated by both primary and secondary lighting systems must be provided to any enclosed area.

Equipment Use – Plant, Machinery, Scaffold Towers, Ladders, Cranes, Forklifts

The use of machinery / scaffold towers, ladders or any other identified equipment shall only be used by competent parties. Required equipment use must be listed within your risk assessment to plan for safe usage.

Cranes and forklifts can only be handled by the organisers’ freight forwarding company. Exhibitors/ contractors are not allowed to engage or hire their own forklifts: these are strictly prohibited for safety reasons. If you have any queries or specific requests then please contact us.

Flooring

Space only stands do not include floorcovering and exhibitors must make their own arrangements. To view Flooring options click here

Gangway carpet and stand carpet cannot be the same colour unless the stand has a platform and then carpeted. Gangways must be clearly identifiable.

You must use NEC Approved tape and we would like to advise you that we currently have two NEC approved suppliers who can supply this tape:

Le Mark Self Adhesives https://www.lemark.co.uk and ISA Tape https://www.isatape.co.uk .

The Exhibitor will be responsible for any damage to the floor coverings, in or around the stand. Any damage caused to the carpet by an exhibitor or their contractor will be replaced and the cost of replacement charged to the Exhibitor.

Floor loading

The floor loadings are limited to 20 tonnes per square metre. Any unusual loads must be discussed with the organisers prior to the build up. Failure to do this may result in items being unable to be brought into the hall.

Fumes

Contractors have a duty to exercise proper controls over the release of harmful fumes and if necessary, carry out a COSHH assessment (see hazardous substances). Engines of vehicles in the halls must not be left on idle. Where this is unavoidable i.e. for cranes, the lifting supervisor is responsible for ensuring that the fumes caused by combustion do not build up in the halls, service tunnels or basements areas as a result.

Gangways

No part of any stand or exhibit, including fascia, signs, lighting, corner posts, etc., shall project into or over the gangway or obscure any fire or exit signs and the Organiser reserve the right to remove any such item. It is strictly forbidden to build across gangways. Emergency gangways must always be kept clear.

Hanging Wires

Hanging wires are not to be left hanging below head height and must be marked with tape.

Hazardous substances

Hazardous substances are not to be brought into the halls unless essential. The use of hazardous substances must be subject to a COSHH assessment. Contractors must declare the use or display of hazardous substances as a special risk. Where the nature or hazardous potential of a substance cannot be established, it will be excluded from the hall.

Stand Height

The permitted maximum height of a stand will be 4m, if you would like to build over this height please email the Organisers for permission.

Machines

If you are planning on exhibiting a machine, please note that you need to fill in the H&S Declaration and provide a risk assessment.

Materials

All construction materials must comply with the regulations stipulated in the eGuide.

Decoration materials used for stand dressing must be flame proofed or purchased already treated by use of the appropriate chemical. Please note that artificial plants and flowers are combustible and give off toxic fumes, therefore not acceptable. Silk-type flowers are acceptable, providing they are fireproof or have been treated and marked as such.

Employment or use of building materials that contain asbestos or products that contain asbestos or any other hazardous materials is prohibited.

Chip board or low density fibreboard materials are prohibited in space only builds.

Stand Numbering

All space only exhibitors must display their company name and stand number prominently on their stand so that they can be viewed from each approaching gangway. This will assist visitors in locating their position within the hall and finding the stands they wish to visit.

Open Sides

On stands with three open sides or less ("part-island stands") the Exhibitor is obliged to erect a dividing wall no less than 2.5m high between their stand and any other stand. Exhibitors are responsible for ensuring that their Contractor leaves any such walls in a clean and finished state in one colour with no branding or logos on the reverse of your walls overlooking neighbouring stands or gangways.

Onsite Inspection

Your stand approval is always subject to onsite inspection. A structural engineer will be on-site during the build period to inspect ALL space only stands in addition to those stands classed as complex. All complex stands must be completed by 14:00hrs on the last build day in order for the sign off to be completed and the certificate issued. For all complex structures a fee of approx. £435 + VAT will be charged by Roar B2B direct to you or your contractor to cover such on-site assessments and certificate costs. Please make sure that your contractor is aware of this charge in order to avoid delays in construction approval.

Personal Protective Equipment

All onsite individuals must be familiar with the H&S information before entering the halls during any stage and use appropriate Personal Protective Equipment correctly.

Site boots or appropriate safety shoes plus a high vis are mandatory. Please ensure you and your team come to site with the appropriate PPE or access to the halls will be denied.

Pillars on Stand

If there are pillars within the stand space, these may be enclosed up to the maximum height of your stand. It is recommended to add a 20cm margins to the pillars to avoid any damage. Painting, wallpapering, or affixing anything directly on/to the pillars are prohibited. Fire extinguishers and technical installations on pillars always need to remain accessible.

Platforms

Platforms should be avoided wherever possible, in order to provide level access to exhibits and services.

Where the use of platforms is unavoidable, they should not exceed 170mm in height (one step) and consideration must be given to accessibility for people with disabilities in compliance with the Equality Act 2010.

The distance between supporting timbers of platforms constructed from battens (25mm thick minimum) and sheet materials (plywood or MDF, 18mm minimum), must not exceed 400mm from centre to centre.

Platform corners must be splayed, rounded or angled to prevent sharp corners and tripping hazards.

Where a bevel edge is applied to the perimeter of a platform, it must be conspicuous.

Platforms must be of a strength and stability sufficient to carry and distribute the weight of the stand fitting, stand personnel, visitors and exhibits having regard to the loading limits of floors.

When laying platforms on your floor space, please pay special attention to the area marked out for your stand. Failure to build to the marked-out area will result in delays to the laying of the gangway carpet, and any additional costs incurred by the Organiser will be passed back to the relevant exhibitor. Please ensure your stand contractors are aware of this.

For more information, please refer to the guidance in the eGuide

Rigging

Rigging is only permissible for Stands who have paid the £1,950+VAT Sponsorship fee to the organisers.

Permission will only be granted after written request and payment to the exhibition organisers. All Rigging must be included in your stand design and approved by our H&S Partner before ordering services. All rigging related services must be carried out by the venue riggers.

If any rigged structures are higher than your dividing back walls the following must be adhered to:

- Structure with branding facing the dividing wall must be stepped in at least 1m from the dividing wall.

Complex Rigging

Complex Rigging or Suspended Loads/Structures refer to rigged, custom-built/bespoke structures including items that have been constructed from non-modular materials, e.g. wooden structures and exhibits.

An additional structural sign off is required which will incur a charge of £435 + VAT payable by either the stand contractor or exhibitor.

Ramped Access

The use of platforms should be avoided wherever possible, in order to provide level access to exhibits and services. Where the use of platforms is unavoidable, they should not exceed 170mm in height (one step) and ramped access should be provided for people with disabilities. It is the exhibitors responsibility to remove all barriers to service and make their stand accessible to wheelchair users to comply with The Equality Act.

- If constraints necessitate an approach of 1:20 or steeper, an approach incorporating a ramp should be provided.

- A ramp must be either readily apparent or the approach to it clearly sign-posted.

- The gradient of a ramp flight and its going between landings should be in accordance with the table supplied in the eGuide

- Ramps shall have a minimum, unobstructed width of 1.5m.

- The ramp surface must be slip resistant, especially when wet and of a colour that contrasts with that of the landings

- A landing at least 1.2m long and clear of any door swings or other obstructions must be provided at the foot and head of the ramp.

- Intermediate landings must be at least 1.5m long and clear of any door swings or other obstructions.

- Intermediate landings at least 1800mm wide and 1800mm long must be provided as passing places when it is not possible for a wheelchair user to see from one end of the ramp to the other, or if the ramp has three flights or more.

- Handrails must be provided on both sides of a ramp which has a gradient steeper than 1:20. Where it is impractical to comply with this legal obligation, a risk assessment must be provided to and approved by the organiser.

- Where the change in level is no greater than 300mm, a ramp should be provided instead of a single step.

- Where the change in level is 300mm or more, 2 or more clearly signposted steps should be provided in addition to the ramp.

- All landings should be level, subject to a maximum gradient of 1:60 along their length.

- A kerb at least 100mm high, which contrasts visually with the ramp or landing, must be provided on the open side of any ramp or landing, in addition to any guarding required.

Safe Behaviour

Unsafe behaviour, or conditions may result in work being stopped and require additional controls to be implemented to rectify issues prior to stand activities continuing. No resolution may result in offenders being asked to leave the site.

Special Risk Items & Exhibits/ On-stand Activities

For more information on having high risk items such as water features, heavy machinery, vehicle movement, contact the H&S Partner as further approval will be required.

If you are planning to use any special effects on your stand, you must inform the organisers as soon as possible by email.

Special effects include (but are not limited to) lasers, strobe lights, and pyrotechnics and smoke machines.

The information, which will be required, includes a risk assessment and full details of the operator and manufacturer. Certification from an independent specialist may also be required, and any costs associated with this will need to be covered by the exhibitor.

Smoking

Smoking is not permitted in the halls at any time. Offenders may be asked to leave the halls and the exhibiting company will be informed.

Travel Distance

Adequate means of escape must be provided from all stands. The travel distances from any part of the stand to the gangway must not exceed 25m.

Walling

Walling In

- Walling in on open sides must not exceed one third of the total run of meterage of each open side and no run of walling can exceed 4m in length. There will be no exceptions.

Runs of walling

- Solid walls along gangways edges are not permitted. Stands must be suitably opened so as not to cause offence to neighbouring exhibitors or breach fire regulations.

- Walls should not exceed 4m in length or at least, 2/3 should remain open. Should you have a wall exceeding these measurements they should either have natural breaks, see-through glazed panels, at least, 1m wide or other such features at regular intervals. Each stand will be assessed individually upon receipt of drawings by the organiser.

Glass walls and mirrors

- Any furnishing or wall elements made with full length glass or mirrors must be properly marked and protected from impact. Glass walls used must comply with current standards with regards to their characteristics and installation system. If glass walls are installed along the routes used by the public, they must be shatterproof. Glass walls must comply, in terms of glass type and installation, with current UNI standards.

Waste

All stand fittings and waste materials must be cleared from the Halls and loading bays by the end of the break down period.

Roar B2B and the venue cannot be held responsible for any items left on your stand, in the aisle or in the loading bays after tenancy and charges will apply to the Exhibitor for removal of these items.

Welding

Welding will not be permitted unless a hot work permit is obtained from the Venue, subject to advance submission of a method statement and risk assessment before any work is carried out on-site.